导读:The speed synchronization and phase synchronization of Pampers diapers making machine are all controlled by servo motor + PLC. The main machine is supplied by fiber collector, the thickness can be adjusted at any time, and the waste can be recycled.Lint pulp and absorbent paper package, mesh press and finalize the design, the use of cotton core does not break, do not shift.

The speed synchronization and phase synchronization of Pampers diapers making machine are all controlled by servo motor + PLC. The main machine is supplied by fiber collector, the thickness can be adjusted at any time, and the waste can be recycled.Lint pulp and absorbent paper package, mesh press and finalize the design, the use of cotton core does not break, do not shift.The three-dimensional protective material is cut in the machine and formed by hot pressing, which can be combined with elastic to form the three-dimensional protective material and prevent side leakage. The whole machine is driven by servo conveyer, the number is changed digitally, and the front waist is attached by servo positioning and cutting to ensure that the pattern is consistent with the phase.

Main Features:

1.Touch screen for man-machine conversation;

2.Servo motor inverter optional drive & PLC control system;

3.Cell mill;

4.Drum forming;

5.SAP applicator;

6.Active unwinding, constant tension control and auto splicing are adopted for raw materials;

7.Auto detecting & alarm for material exhausted or omission; auto reject for material joint;

8.Pase can be adjusted during operation;

9.Bi-folding & tri-folding unit;

10.Product auto counting & stacking.

Main Structural device:

1.Cell mill;

2.Suction fan;

3.Drum forming;

4.SAP applying applicator;

5.Tissue wrapping device;

6.Core compacting device;

7.Core cutting device;

8.Elastic waist applying device ;

9.Elastic ribbon unwinding device;

10.ADL applying device;

11.Cuff embossing device;

12.Frontal tape applying device;

13.Side tape applying device;

14.R cutting device;

15.Final cutting device;

16.Final folding device;

17.Waste rejecting device;

18.Safty door;

19.Stacker (to be ordered).

Finished Products structure:

Finished products

Related Products

baby pull up diaper machine

lady sanitary napkin production line

adult diaper making machine

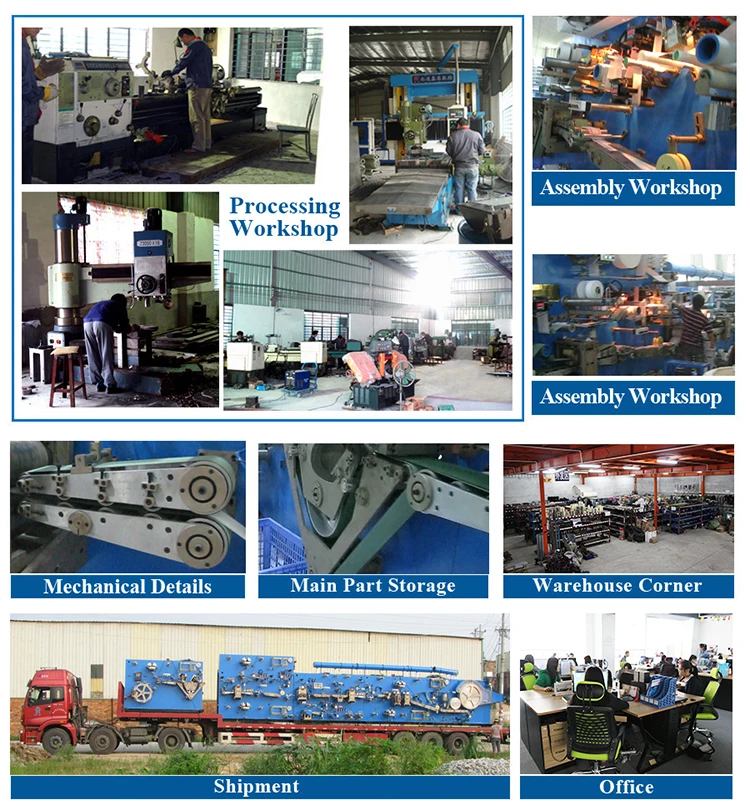

Our Company

HI-CREATE is manufacturer for disposable hygiene products machinery development, design and producing, mainly in production line for baby diaper , sanitary napkin, waistband diaper , training pant(pull up) diaper, adult diaper , and a series of household paper, disposable products processing equipment for toilet paper, tissue paper, and napkin paper.

Certifications

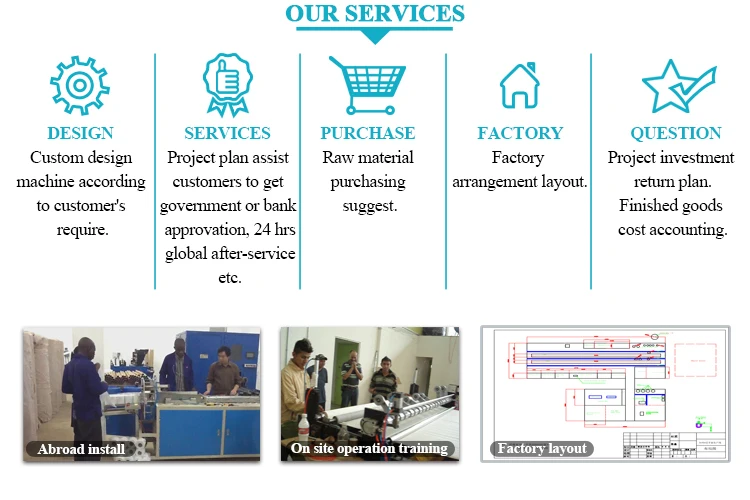

Our Service

Packing & Delivery